Understanding the Vital Role of Tube Fittings Manufacturers

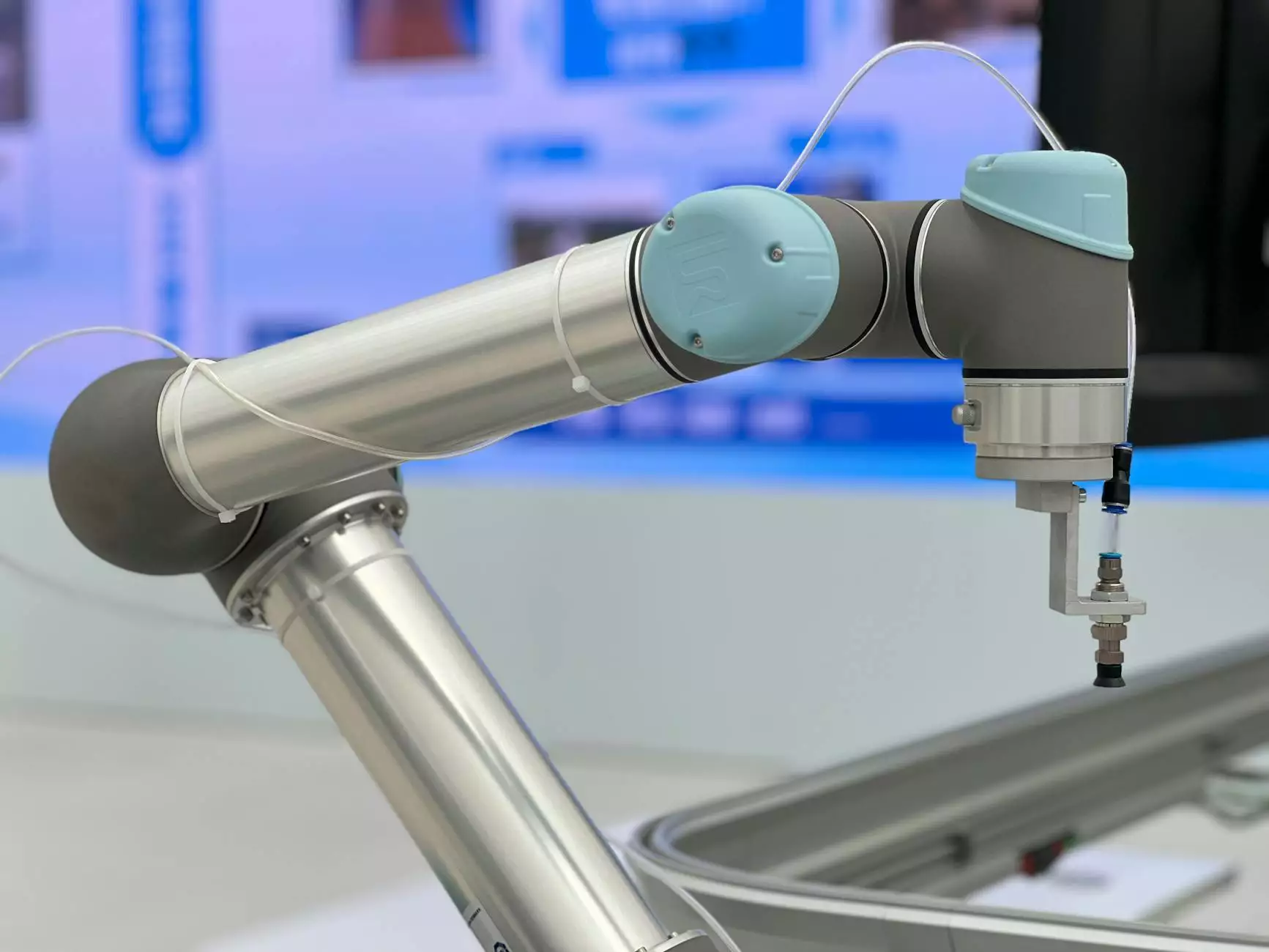

In today's evolving industrial landscape, the importance of precision-engineered components cannot be overstated. Among these components, tube fittings play a crucial role in ensuring the efficiency and safety of fluid transfer systems across various applications. As industries grow and technology advances, the demand for reliable and high-quality tube fittings has surged, placing tube fittings manufacturers at the forefront of this essential supply chain.

What are Tube Fittings?

Tube fittings are mechanical devices designed to connect tubing to various elements such as pipes, valves, or other tubes. These fittings are integral for creating secure and leak-proof connections, which are paramount in many industrial applications.

The Importance of Tube Fittings

Tube fittings possess numerous advantages that make them an essential component in industries such as oil and gas, chemical processing, food and beverage, and pharmaceuticals. The primary importance of tube fittings includes:

- Leak Prevention: Tube fittings provide a secure connection that minimizes the risk of leaks, which can be hazardous and costly.

- Pressure Resistance: Many tube fittings are designed to withstand high pressures, making them suitable for critical applications.

- Easy Installation: Most fittings can be easily installed and removed, allowing for quick maintenance and system modifications.

- Versatility: With multiple designs and materials available, tube fittings can be used in various applications across different industries.

Types of Tube Fittings

There are several types of tube fittings offered by tube fittings manufacturers, each designed for specific applications. Understanding these types will help you make informed choices when selecting fittings for your projects.

1. Ferrule Fittings

Ferrule fittings are widely used in medium to high-pressure applications. They consist of a fitting body, a ferrule, and a nut, ensuring a strong grip on the tubing. These fittings are popular for their reliability and ease of use.

2. Forged Pipe Fittings

Forged pipe fittings are manufactured through shaping processes that provide enhanced strength. They are ideal for applications requiring high integrity and durability.

3. Threaded Pipe Fittings

Threaded fittings allow for easy assembly and disassembly, making them suitable for static and dynamic applications. They are commonly used in plumbing, HVAC, and oil and gas industries.

4. Flanges

Flanges are flat components that connect pipes and allow for easy access for cleaning and repairs. They provide versatility in assembling and disassembling piping systems.

5. Check Valves

Check valves permit fluid flow in one direction while preventing backflow. They are critical in applications where backflow could lead to system failures.

6. Ball Valves

Ball valves are designed with a ball to control flow and are known for their durability and excellent sealing capabilities. They are ideal for applications requiring on-off control.

7. Needle Valves

Needle valves provide precise flow regulation and are commonly used in low-flow applications, contributing to system efficiency.

8. Manifold Valves

Manifold valves ease the connection between multiple lines and assist in the centralized control of flow, which is crucial in complex systems.

9. Double Ferrule Tube Fittings

These fittings offer a two-ferrule design that provides exceptional sealing and grip, suitable for high-pressure applications.

10. Single Ferrule Tube Fittings

Single ferrule fittings are easier to install and are suitable for less demanding applications, making them a popular choice among many users.

11. NPT Fittings

National Pipe Thread (NPT) fittings feature tapered threads to create a tight seal, widely used in plumbing and industrial applications.

Choosing the Right Tube Fittings Manufacturer

When selecting a tube fittings manufacturer, consider the following factors:

- Quality Assurance: Choose a manufacturer that adheres to industry standards and certifications to ensure the quality of the products.

- Product Range: A manufacturer offering a wide range of fittings and related products is beneficial for sourcing all necessary components from one supplier.

- Custom Solutions: Some projects may require specialized fittings; thus, opt for manufacturers that provide tailored solutions.

- Customer Support: Strong after-sales support and knowledgeable staff can assist in resolving issues and guiding selection.

The Benefits of Partnering with Leading Tube Fittings Manufacturers

Choosing reputable tube fittings manufacturers like Techtubes offers many benefits that can impact your operations:

1. Reliability and Consistency

Reliable manufacturers ensure that their products consistently meet quality standards. This reliability is critical in maintaining the integrity of your fluid systems.

2. Enhanced Safety

High-quality fittings contribute to the overall safety of your operations by reducing the likelihood of leaks and failures that could endanger personnel and facilities.

3. Cost-Effectiveness

Investing in high-quality fittings may reduce long-term costs by minimizing maintenance, leaks, and downtime. Quality products often lead to higher efficiency.

4. Innovation

Leading manufacturers are often at the forefront of technological advancements, providing innovative solutions that enhance fluid transfer systems.

Applications of Tube Fittings

Tube fittings are widely used across multiple industries due to their versatility. Below are some common applications:

1. Oil and Gas Industry

The oil and gas sector relies on durable and leak-proof fittings for drilling, extraction, and transportation of hydrocarbons. Tube fittings help ensure the safety and efficiency of operations.

2. Chemical Processing

In chemical plants, the precise flow of potentially hazardous materials is critical. Tube fittings help maintain control, ensuring safe operations.

3. Food and Beverage Industry

Hygienic tube fittings are essential for maintaining the purity and safety of food and beverage products, adhering to strict sanitary standards.

4. Pharmaceuticals

In the pharmaceutical sector, tube fittings facilitate the transport of sensitive materials while adhering to stringent guidelines to prevent contamination.

5. Automotive Industry

Tube fittings are employed in various automotive applications, from cooling systems to fuel lines, highlighting their critical role in vehicle construction.

Conclusion

In conclusion, the role of tube fittings manufacturers is vital in ensuring the efficacy, safety, and reliability of fluid systems across numerous industries. By understanding the different types of fittings available and choosing the right manufacturer, businesses can enhance their operations and maintain the highest standards of quality. Techtubes, as a reputable manufacturer, stands ready to meet the diverse needs of industrial applications with a comprehensive range of tube fittings and components, ensuring that every connection is robust and dependable.